The AI Rare Earth Problem (Week 41-2025)

Many watch the “AI bubble” from the wrong point of view. In fact, AI is not a bubble in the sense that there is a lack of demand; I have explained many times that this is not the case, and that is what makes this technological supercych quite unique.

Instead, and This is the key point: the AI supply chain is very fragile, and anything in it can break, at any time, bursting the bubble, but not because of overinvestment, but rather because of the lack of a strong enough supply chain, to allow us to have the computing needs, to serve AI at scale.

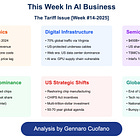

This week in the AI sector: analysis of AI technology bubbles (week 35-2025)

In short, the AI supply chain is so interconnected, interdependent, complex and dependent on so many players (contrary to common belief, everything is in the hands of a few players), that it also has many choke points.

This week in the AI sector: the question of customs tariffs (week 14-2025)

Indeed, remember that for every lithography machine produced, there are likely thousands of small suppliers, supplying the smallest components to make it possible.

For every rare earth material that enters an AI chip’s supply chain, thousands of refineries do.

New Chinese restrictions on the export of rare earths have revealed the most hidden yet critical choke points in the AI supply chain.

In short, China has ruled out that global companies selling products containing certain rare earths from China, accounting for 0.1% or more of the product’s value, must seek permission from Beijing.

Tech companies will likely have a hard time demonstrating that their chips, the equipment needed to make them, and other components fall below that threshold.

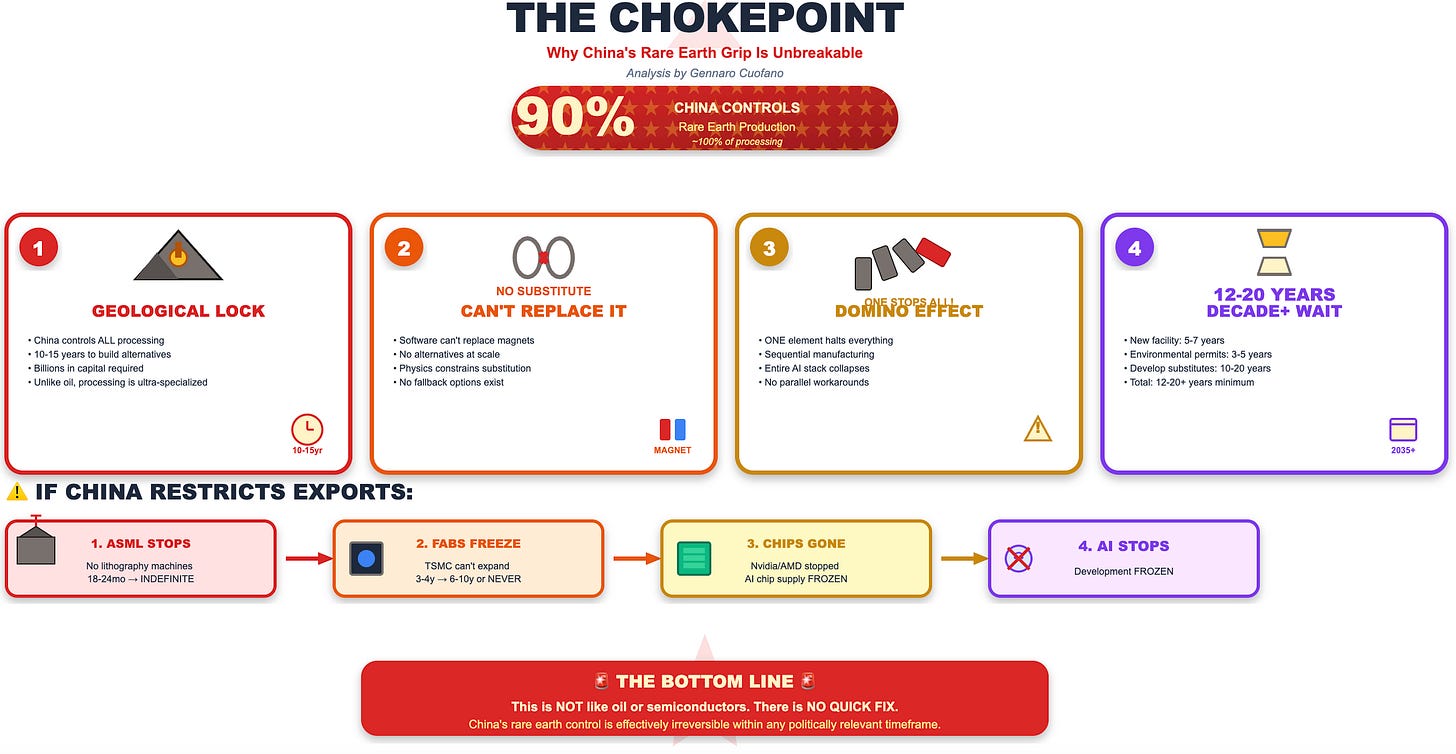

This is not simply tariff escalation or another trade negotiation tactic. This is a precision attack on the one supply chain vulnerability that could truly derail the AI revolution: the physical materials needed to manufacture and operate the computing infrastructure that powers everything from data centers to semiconductors to the machines that make semiconductors.

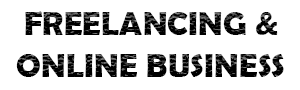

While everyone is focused on semiconductor manufacturing capacity, chip design talent, and AI model capabilities, China produces around 90% of the world’s rare earths. These minerals and the ability to refine them form the basis of modern civilization. These rules could cause a recession in the United States if implemented aggressively, due to the vital importance of capital spending on AI to the economy.

This analysis examines why rare earths are the ultimate supply chain choke point, the structural dependencies that make this threat unique, how this is accelerating decoupling and geopolitical realignment between the United States and China, the cascading effects on AI infrastructure, strategic responses and why most will fail, and the winners and losers in a world constrained by rare earths.

AI is not virtual. It’s deeply physical. And this physicality creates dependencies that cannot be coded, negotiated, or venture funded.

Each layer of the AI stack depends on rare earths.

Data centers, the foundations of AI inference and training, require permanent magnets (neodymium, dysprosium) in hard drives, cooling fans and power supplies. Their fiber optic networks need erbium and ytterbium for optical amplification. Power systems rely on rare earth magnets in generators and transformers. Even cooling infrastructures use europium in phosphors for efficiency monitoring.

Semiconductors – the processors that run AI models – rely on rare earths at every step. Chemical-mechanical polishing uses cerium oxide slurries to flatten wafer surfaces. Phosphores and dopants (yttrium, lanthanum) determine the performance characteristics of the chips. Epitaxial growth requires various rare earths as catalysts and dopants. Advanced packaging uses bonding materials containing rare earth elements.

Chip manufacturing equipment (ASML lithography machines, applied material deposition tools) cannot operate without rare earths. Extreme ultraviolet (EUV) lithography lasers use precision optics made from rare earth elements. Vacuum systems require rare earth magnets in pumps and motors. Robotic handling systems require permanent magnets for precise movement control. Measurement and metrology tools depend on sensors and detectors based on rare earths.

The United States and other countries are investing hundreds of billions of dollars in data centers, making AI a key economic driver. Taking control of the technology from China would potentially allow it to catch up in the AI race and upend the global order.

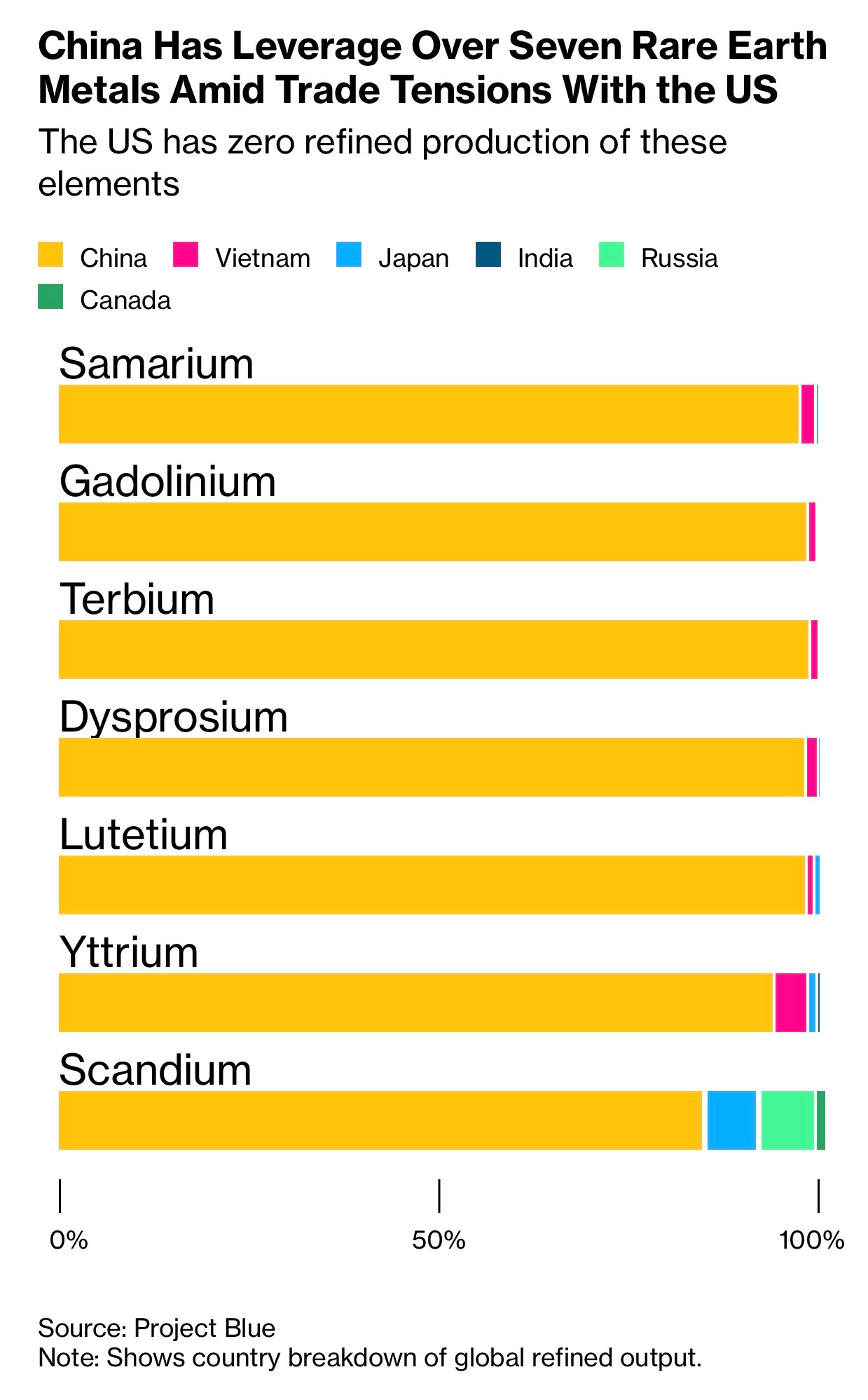

Unlike other supply chain vulnerabilities, rare earth dependencies have four characteristics that make them particularly threatening.

First: geological concentration. Rare earth deposits exist globally, but economically viable deposits are concentrated. China controls not only the mines, but also the entire processing and refining infrastructure. China produces around 90% of the world’s rare earths. Building alternative processing capacity takes 10 to 15 years and billions in capital investment.

Second: technical irreplaceability. You cannot replace magnets with software. No amount of AI optimization can replace neodymium in a motor. The physical properties of rare earths – magnetic, optical, electronic – have no short-term alternatives. Research and development of alternative products has continued for decades with limited success.

Third: cascading dependencies. A missing rare earth can interrupt entire production lines. The rule threatens the supply chain for semiconductors, which are the lifeblood of the economy, powering the phones, computers and data centers needed to train artificial intelligence models. Sequential manufacturing means that a disruption at any time stops everything downstream. You cannot “partially ship” chipmaking equipment that is missing critical rare earth components.

Fourth: long delivery times. Building new mines takes 7 to 10 years from discovery to production. Construction of processing facilities takes 5-7 years. Establishing environmental compliance takes 3 to 5 years. Developing alternative materials could take decades. Total time to establish an independent supply chain: 12 to 20 years minimum.

The combination of these four factors creates what military strategists call a “strategic choke point”:a single vulnerability that, if exploited, can cripple an entire system, regardless of the strength of other domains.

This brings us to today’s structural reality.

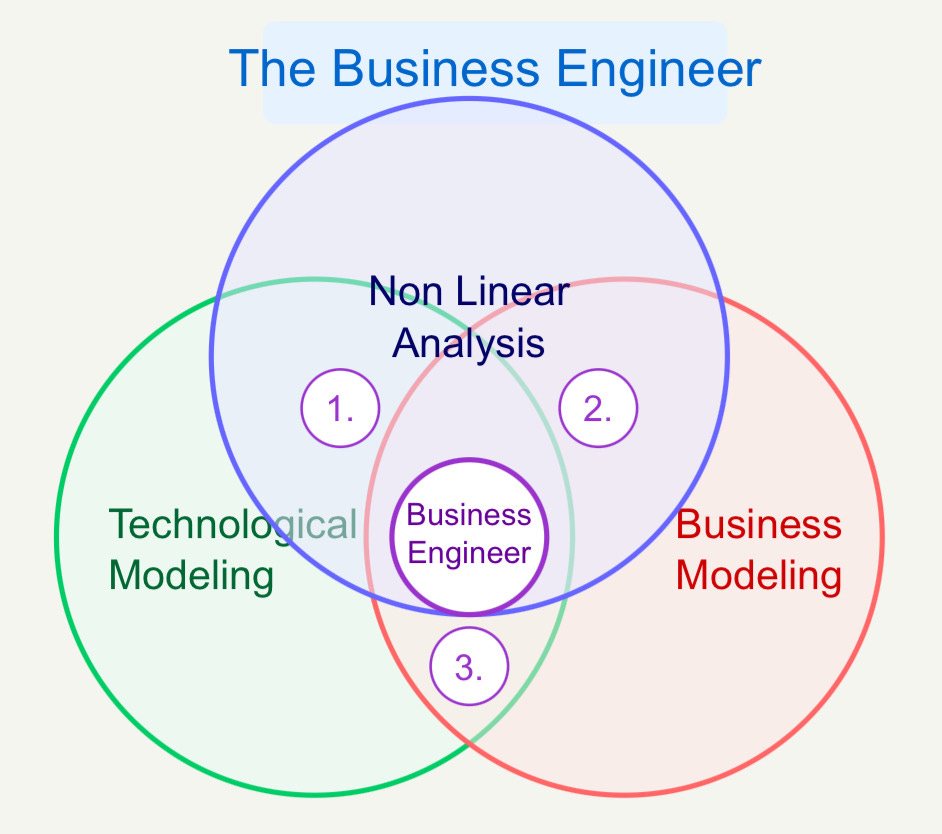

The weekly newsletter is in keeping with the spirit of what it means to be a business engineer:

We always want to ask three fundamental questions:

What is the form of the underlying technology that connects the valuable accessory to its product?

What is the form of the underlying activity that connects the element of value to its distribution?

How can the company survive in the short term while adhering to its long-term vision through a transitional business model and market dynamics?

These non-linear analyzes aim to isolate the short-term hum and noise, identify the signal, and ensure that the short-term and long-term can be reconciled.

ـــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ

Soon, there will be articles covering various topics, such as:

Insurance, Loans, Mortgage, Attorney, Credit, Lawyer, Donate, Degree, Hosting, Claim, Conference Call, Trading, Software, Recovery, Transfer, Gas/Electicity, Classes, Rehab, Treatment, Cord Blood, Best mesothelioma lawyer, Truck accident lawyer, Buy life insurance online, Business VoIP provider, EMR software for clinics, Structured settlement companies, motorcycle injury lawyer, motorcycle injury attorney, spinal cord injury attorney, birth injury attorney, auto accident injury attorney, spinal cord injury lawyer, car injury attorney, motorcycle accident injury attorney, catastrophic injury lawyer, birth injury lawyer, workplace injury attorney, motorcycle injury attorneys, head injury lawyer, personal injury attorneys, traumatic brain injury attorney, train accident lawyer, brain injury attorney, auto injury attorney, serious injury attorney, personal injury lawyer, truck injury lawyer, injury attorneys, back injury lawyer, injury lawyer near me, injury lawyer,

If you would like to see these articles, please write so in the comments.